By Daniel Bloch, Sustainable Aviation Fuels (SAF) Specialist at IATA

Back in 2021, the airline industry passed a Net Zero 2050 resolution at the 79th IATA AGM in Boston, which was subsequently supported through the adoption of aviation’s Long Term Aspirational Goal (LTAG) by the UNs International Civil Aviation Authority (ICAO) and its associated member states last October.

The key element to the industry’s decarbonization strategy is the scaling of Sustainable Aviation Fuel (SAF) production and deployment. To that effect, it is forecast that 65% of the sector’s emission abatement can be achieved through SAF, as part of the Net Zero 2050 movement.

Despite an approximate tripling of SAF supply witnessed in 2022 relative to 2021, production still needs to increase exponentially for aviation to reach its decarbonisation goals. Central to this necessary increase will be SAF’s feedstocks, spanning their availability, sustainability integrity and compatibility with biorefining technology.

Overall, there are three fundamental concepts that are essential to understanding feedstock:

As a non-fossil source, SAF feedstock will constitute a form of waste or purpose grown energy crop that has been cultivated on degraded or marginal land. Conversely, the direct use of commodities like food crops are not considered a viable feedstock for SAF production. Rather, the essence of waste feedstock is to repurpose surplus materials, which are derived from pre-existing processes or cycles.

In turn, these waste feedstocks, by design, do not require the use of any additional resources such as land (or land clearing), water, fertilizer etc. Similarly, in the case of purpose-grown energy crop feedstocks, these projects will target the usage of otherwise non-utilized land, due to their marginal state or degraded state.

Another important consideration to make is that if these waste materials or degraded lands are not repurposed, they themselves can create negative socio-economic and environmental effects. In most cases, when left unattended, these wastes will be sent for incineration, urban landfills or burying (thereby creating another emission profile), whilst areas of degraded land will be left to propagate and further reduce the productivity of the surrounding environment.

| FEEDSTOCK | If feedstock is not repurposed, socio-economic implication: |

|---|---|

| Waste fats, oils & greases | Sent for incineration or landfill |

| Agricultural wastes | Toxifies waterways, damages soil productivity, sent for incineration |

| Forestry wastes | Sent for incineration, catalyst for forest fires |

| Urban landfill | Methane & nitrous oxide emissions, reduces carbon capture |

| Wet wastes | Exhausts sewerage systems, toxifies waterways |

| Forestry wastes | Sent for incineration, catalyst for forest fires |

| Degraded land | Soil productivity loss, biodiversity loss, high salinity levels |

With that in mind, CORSIA’s Eligible Fuel Criteria serve as a key point of reference to identify viable feedstock for SAF. As represented below, a range of carbon, environmental and socio-economic factors must be considered for a feedstock’s aggregation and/or cultivation process, beyond just emission reduction potential.

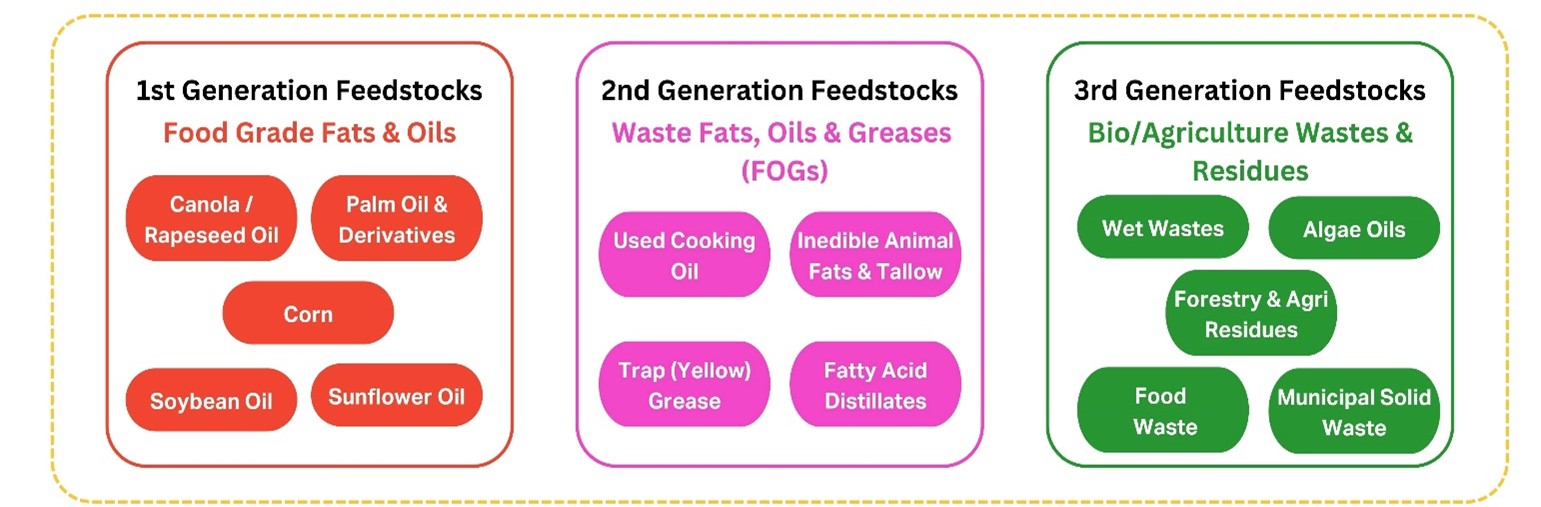

Feedstocks can be largely broken down into three generations, with a non-exhaustive list represented below:

The generations of these feedstock are predominantly determined by their:

To that effect, 3rd generation feedstocks are the most attractive inputs for SAF production, if the relevant biorefining production capacity is commercially available and operating. Contrastingly, 1st generation feedstocks that are largely made up of food grade crops, fats and oils, are in most cases facing challenges to prove and uphold the industry’s identified sustainability criteria. Specifically, the industry is intent on ensuring feedstocks associated with deforestation, food-chain competition and biodiversity loss, are not incorporated within its viable feedstock mix.

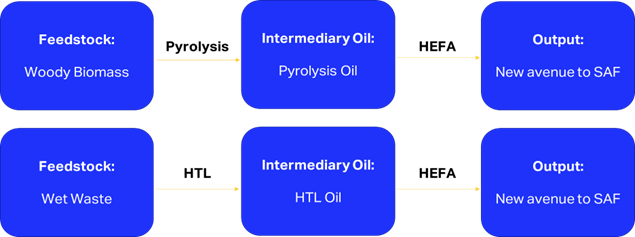

With that said however, approximately 85% of future SAF facilities over the next five years will come from Hydrotreatment (HEFA) production technology. This pathway is typically associated with 2nd generation feedstocks like used cooking oil, inedible animal fats (tallow) and industrial grease, of which are all perfectly viable feedstocks, but are inherently constrained by their natural limitations of how much can be produced from industrial and food processes.

Invariably, this equation points to the need to diversify SAF, to pursue both the industry’s overall volumetric needs for SAF, as well as to foster the creation of SAF with the highest levels of positive sustainability impact. In turn, we can identify three avenues to achieving SAF diversification:

As previously suggested, when not repurposed, waste feedstocks and degraded land are linked to a wide range of negative socio-economic and environmental externalities of their own. On the other side of the equation, projects aimed at aggregating wastes or recultivating degraded land (3rd generation feedstock) have several positive socio-economic effects, which become a major pull factor for attracting institutional and critically, government investment. In the pursuit of 3rd generation feedstock projects, aviation can engage with governments on a range of levels likely to resonate far further than just the end-product concept of SAF.

Playing further into the hands of 3rd generation feedstocks are the impending emergence of nature-based finance and policy schemes. In the past year alone, developments across the Global Biodiversity Framework, the Taskforce for Nature Related Financial Disclosures, and the growing potential for Nature Repair markets, work to portray SAF’s compatibility with the way business will transition in the near-term. In particular, 3rd generation projects directly foster the values of nature-based solutions, and in turn, can directly work to future-proof SAF’s long-term viability and investment proposition.

With that said, a Golden Trifecta for feedstock identification becomes apparent. These trio of factors can help to collectively promote the scaled ramp-up of SAF, achieve the highest level of sustainability integrity and drive investment attraction from governments across the globe.

Overall, SAF production doesn’t just redirect demand away from fossil fuel. Crucially, SAF’s key driver, the feedstock, can:

For more information on SAF, please refer to ATAG’s Beginner’s Guide to SAF