The decarbonization of the aviation sector relies mainly on the deployment of Sustainable Aviation Fuel (SAF). These fuels are similar to oil-based jet fuel but are produced from renewable resources (plants or CO2). Before they can be used in commercial aviation, they are subject to a very rigorous certification process involving many aeronautics stakeholders. The aim is to ensure that they meet the many technical requirements while guaranteeing passenger safety. The American Society for Testing and Materials (ASTM International) is the only certifying body for aviation fuels. To date, it has certified only around ten SAF production technologies.

Global Bioenergies, a French company specializing in synthetic biology, has managed to profoundly modify the DNA of bacteria to produce by fermentation a molecule well known to the petrochemical industry: isobutene. Isobutene can then be converted into SAF through two simple green chemistry transformation steps. Each of these steps are referred to as "IBN-SPK" - the name chosen by the Company for its technology - which fall under the ASTM D7566 standard for the production of SAF. More specifically, it is listed in Appendix 5, dedicated to fermentation technologies, alongside Alcohol-To-Jet ("ATJ-SPK") technology, the first plant of which has just been inaugurated in the United States.

Sustainable Aviation Fuel from Global Bioenergies' technology can now be blended up to 50% into the fuel tanks of all commercial aircraft worldwide, without any modification to existing equipment or infrastructure.

This technology is compatible with a wide range of sugar sources, making it easy to use in varied geographies, in particular sugars from corn in North America and second-generation sugars in Europe (wood sugars, for example).

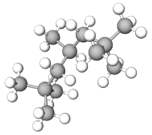

All SAF technologies today produce linear molecules. Jet fuel, however, requires the use of branched molecules. It is possible to transform linear molecules into branched molecules, but this step, known as "isomerization", results in the loss of part of the initial product. This necessary step for SAF actors entails a loss, proportional to the level of branching sought, that can exceed 20%. It turns out that the IBN-SPK technology developed by Global Bioenergies produces highly branched molecules. No isomerization step, likely to lead to a loss of material, is therefore necessary.

IBN-SPK produces highly branched molecules.

Current SAF production accounts for just 0.1% of all the world's jet fuel and is set to increase 100-fold over the next 10 years. SAF, in general, produces around 3 times less CO2 compared to oil-based kerosene. Their widespread use will help to decarbonize aviation, which is urgently needed for the planet.

Marc Delcourt

Co-founder and CEO

Coline Araf-Le Pache

Deputy CFO