With 1,000,000 ULDs valued at over $1 Billion being used for air transport, it is crucial to maintain their airworthiness. This is true not just to protect the unit load device (ULD) from any damage but to ensure the safety of passengers, crew and aircraft as well as operational personnel on the ground.

IATA just released the 2023 Cargo Operations Trend Report. This report covers new regulatory requirements, insights into the surge of e-commerce packaging & shipping and much more.

Download your copy of the 2023 Trends - Cargo Operations Report

The ultimate purpose of ULD serviceability check is to maintain the continued airworthiness of ULD and ensure only airworthy ULD is loaded aboard aircraft.

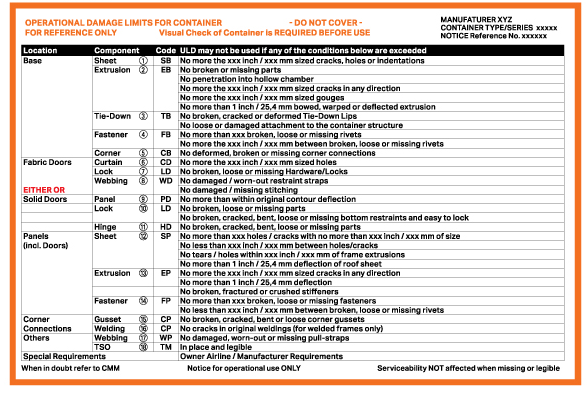

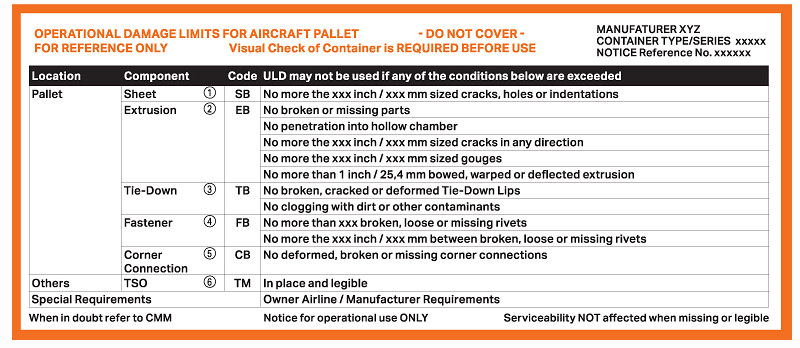

In the course of daily operations each aircraft ULD shall be checked against its damage limits prior to build-up, prior to dispatch to an aircraft, prior to loading aboard an aircraft, when unloading from an aircraft, after ULD break-down, during inventory check, and when being interlined, interchanged, or transferred between parties prior to acceptance (see ULDR Section 6, OS 6/00). Such limits are established by the ULD manufacturer and are part of the ULD certification and contained in the ULD manufacturer’s Component Maintenance Manual (CMM). Due to the wide variety of different ULDs and the fact that the appropriate CMMs are not always available, it has become necessary to have a means of indicating the ULD operational damage limits on the unit itself. For this reason, the standard formats and general content of the ULD Operational Damage Limits Notice (ODLN) for certified aircraft ULDs and restraint strap have been developed by IATA (see ULDR Section 7, SS 40/3). The ODLN ensures access to the required damage limit information, facilitating ULD serviceability check and visually detectable damage check in the field and the consequent availability of the ULD for service.

To determine whether a ULD is serviceable or not, a complete ULD serviceability check shall be conducted by checking all the ULD components listed on the ODLN:

A complete ULD serviceability check will become almost impossible once a ULD is built up, because some ULD components are no longer visible, e.g., ULD base sheet and base fasteners are covered or blocked by the content loaded; therefore, in a given ULD operational cycle, a complete ULD serviceability check should be conducted prior to ULD build-up when the ULD is empty.

Based on the safety risk assessment and mitigation strategies and in order to reduce the possibilities of an unserviceable ULD arriving at the ULD build-up workstation, on an optional basis, a complete ULD serviceability check may be conducted after ULD break-down and/or prior to transferring ULD to/from storage in addition to prior to ULD build-up.

Once confirmed serviceable after a complete ULD serviceability check, regular visual checks for any visually detectable damages to ULD components should be performed in the course of ULD operations to ensure the serviceability of a ULD is continuously monitored and verified. If the visually detectable damage is identified during the visual check, refer to that ULD component’s corresponding damage limit on the ODLN to determine if the ULD is still serviceable.

The combination of aircraft pallets and aircraft pallet net is one form of aircraft ULD. Meeting the standard requirements ensures they are safe for flight on board compatible aircraft. Meeting the Operation Specifications provided in the ULDR provides reasonable assurance that aircraft pallets comply with the regulations

Aircraft pallet nets whose purpose is to cover the pallet and restrain the goods within it constitute aircraft ULDs as defined by industry standards and must meet airworthiness requirements. The Operating Specifications for pallet nets are intended for those restraining cargo on certified aircraft pallets and not directly attached to the aircraft structure. There are more pallet net operation specifications that you can find within the ULD Regulations (ULDR).

Aircraft pallet/net operations often require the use of aircraft pallet accessories. Some of the most common accessories are:

4. Aircraft Container Operations

Aircraft containers that are used for baggage, cargo, or mail are also considered to be aircraft ULD and must also meet the requirements outlined in the ULDR. The aircraft containers must be either airworthiness approved (TSO C90) or non-certified and meet all the requirements of aircraft Weight & Balance Manuals as well as applicable international standards.

In the course of daily operations, ULD damage checks should be performed, e.g., prior to build-up, prior to dispatch to an aircraft, prior to loading aboard an aircraft, when unloading from an aircraft, after ULD break-down, during inventory check, and when being interlined, interchanged, or transferred between parties prior to acceptance. To facilitate ULD serviceability check and visually detectable damage check in the field by the operational personnel, IATA designed an ‘orange sticker’ called ULD Operational Damage Limits Notice (ODLN) as an industry standard that facilitates operational staff in the field to conduct ULD damage checks.

However, what to do when damage to a ULD component is detected?

Refer to that damaged ULD component’s corresponding damage limit on the ODLN:

Once the ULD is determined unserviceable, the following procedures are recommended:

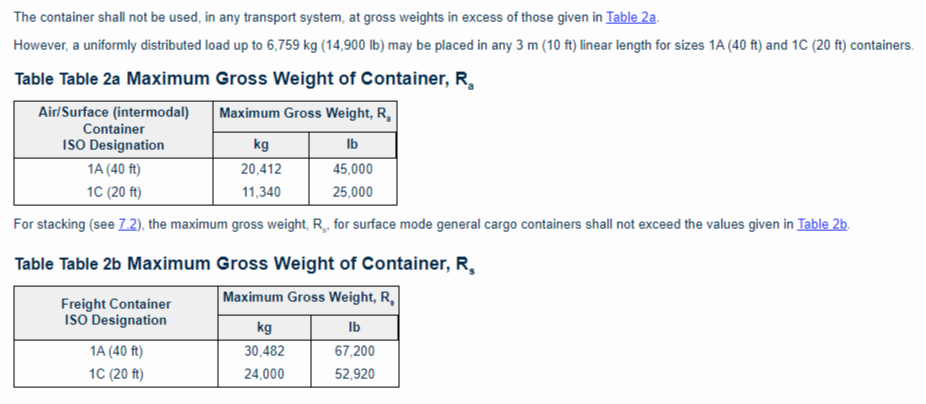

When shipping ULDs by air, the maximum gross weight limitation and the ULD center of gravity must be complied with to ensure they are not exceeded. All unit load devices used for cargo, baggage, or mail must be weighed before being loaded onto the aircraft.

There is maximum gross weight limitation at a given ULD position on the aircraft. The accuracy of the ULD gross weight helps verify if the limitation is exceeded. The ULD gross weight also helps determine the aircraft's overall weight, which is also essential to flight safety.

The ULDR gives specifications for determining and meeting the maximum Centre of Gravity limitations applicable to ULDs based on certified aircraft ULD’s airworthiness approval and/or aircraft Weight & Balance Manual for non-certified aircraft ULDs. Determining the center of gravity is essential for ensuring that the

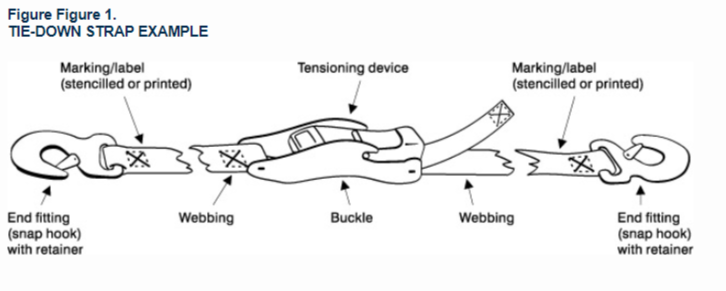

Restraint strap utilization and tie-down calculations of a ULD pallet (aircraft pallet) are other aspects of ULD safety operations requirements that must be taken into account as they are essential to flight safety. They require strict compliance with the aircraft Weight and Balance Manual (WBM) and the general rule in Subsection 3 of OS 6/07 in the ULDR. The primary tie-down strength depends upon the aircraft type the ULD is being carried on.

The ULD protection wrapping protects the content from the weather, theft, and other instances that might damage the contents being shipped. Improper ULD wrapping was evidenced to be detrimental to aircraft systems through either bringing undue amounts of water or snow into cargo compartments, where they have been known to clog compartment drainage systems, or interfering with the cargo loading system to the extent complete restraint cannot be achieved or visualized.

The protective wrapping does not include the temporary coverings sometimes used on pallets over the nets for ground transportation or storage.

Load shoring, which means load spreading, is necessary when ULD bases have heavy concentrated loads. Shoring can be done either laterally in relation to the aircraft centerline, longitudinally, or both, all of which can be found in the manual.

The Fire Containment Covers (FCC) help prevent a fire that might occur in cargo and endanger the safety of the aircraft during flight. Due to the importance of their nature, they are built to precise specifications, and a preliminary check must be performed that meets the safety standards and the designed fire containment capability as outlined in the ULD Regulations (ULDR).

Another important ULD operation specification is the Fire Resistant Containers (FRC). The purpose of this container is to prevent fire from occurring in the cargo loaded in the FRC and causing damage to the aircraft during flight.

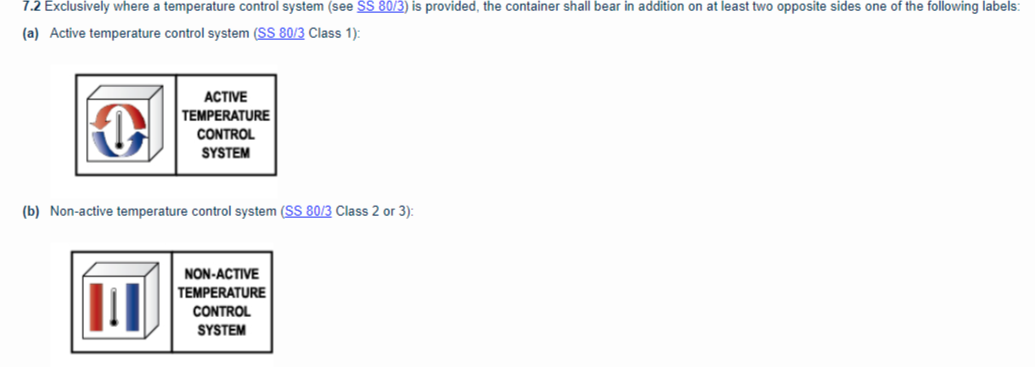

Thermal and temperature-controlled containers (TCC) need specific care to maintain both their cooling effectiveness to ensure that perishable goods are not damaged and their airworthy condition. Detailed operating requirements can be found in Section 6, OS 6/18 of the ULDR.

There are other Operating Specifications that can be found in Section 6 that relate to the operating requirements for aircraft pallets, aircraft pallet nets, aircraft containers, restraint straps, Fire Containment Covers, Fire Resistant Containers, vehicles, aircraft engines, etc.

Utilizing the ULD Regulations provides the user with step-by-step instructions and the most current regulations regarding the handling of unit load devices; however, you may need more training.

Regular training for those directly involved in unit load device operations is required. Since the use of ULDs varies, all personnel must be well-versed in the most current safety and usage instructions. IATA offers courses in ULD Build-up and ULD Operations.

The build-up course teaches such things as the requirements concerning serviceability, storage, and transportation and identifying the special build-up procedures for odd-shaped cargo, and gaining knowledge in aircraft terminology, fleet, and contours.

The ULD operations course covers topics such as what is required to ensure safe and efficient ULD operations and understanding why ULD handling is critical to flight safety and operations.

IATA provides training courses with certification for all of those who are involved in the handling of ULDs. The certification is given to those who receive an 80% or higher in the course. These trainings are to help personnel better understand the rules and regulations and best practices surrounding ULDs.

The first course is the Build-up Certification. It is intended for:

The second course is ULD Operations. Personnel directly involved in ULD operations are expected to train regularly on tasks related to their job function. This course is recommended for:

Rules, regulations, and best practices are needed within the air transport industry to ensure that the minimum industry standard is being complied with across the air cargo supply chain by both airlines and non-airline parties. Cargo cannot talk, standardizing these rules, regulations, and best practices means everyone is trained in the same manner, shares the same knowledge, and is competent in their job to ensure safety, security, efficiency and quality in air cargo operations. Following strict safety, protocols mitigate incidents among personnel and costly damage to equipment and aircraft.

IATA ULD Regulations (ULDR) contain all the applicable requirements of the International Civil Aviation Organization (ICAO) Annexes and Civil Aviation Authorities (e.g., EASA and FAA) regulatory requirements/ guidance as well as aircraft Weight & Balance Manual common rules. IATA has included additional requirements to reflect applicable technical specifications from international standard organizations (e.g. SAE and ISO) and industry agreed operating requirements. Therefore, IATA ULDR is considered one means of compliance containing a single set of regulations for all parties involved (e.g. Airlines, Ground Service Providers (GSP), Shippers/ Freight Forwarders, ULD manufacturers, and ULD service providers) to conform to all legally applicable and industry agreed regulations."

It is "updated annually by the IATA ULD Board (ULDB) in consultation with IATA Member airlines, IATA ULD Technical Advisory Group (ULDTAG), IATA Operational Advisory Group (ULDOAG), IATA Strategic Partners, aircraft manufacturers, regulatory authorities, professional institutions (International Standards Organization-ISO and the Society of Automotive Engineers-SAE International), ULD manufacturers and ULD service providers," according to the ULDR.

The airline industry and laws and government regulations surrounding it are constantly changing to meet current and future needs. For nearly 80 years, IATA has worked diligently to prioritize airline safety, including handling unit load devices. Over the years, IATA has learned that in order to keep stakeholders aware of the most current information, yearly manuals are required.

Parties across the air cargo supply chain such as airlines, ground service providers, freight forwarders and even shippers rely on having a trusted resource they can refer to for all their safety standards and regulations compliance. IATA is this trusted resource. You can get further information regarding how to conduct a ULD serviceability check and more by getting the ULD Regulations (ULDR) today. However, the ULDR might not be the only manual you need. Learn more about IATA's other manuals.